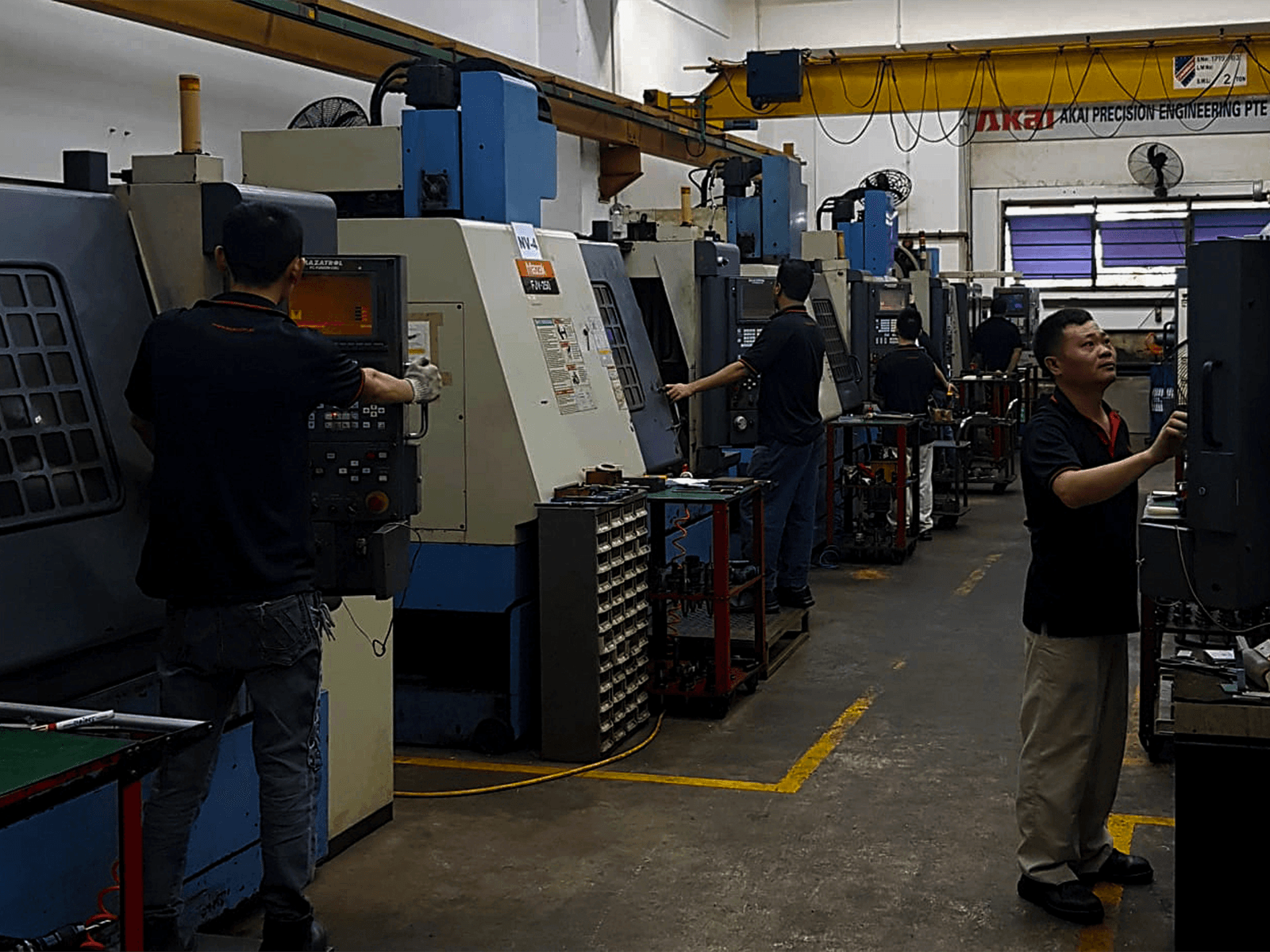

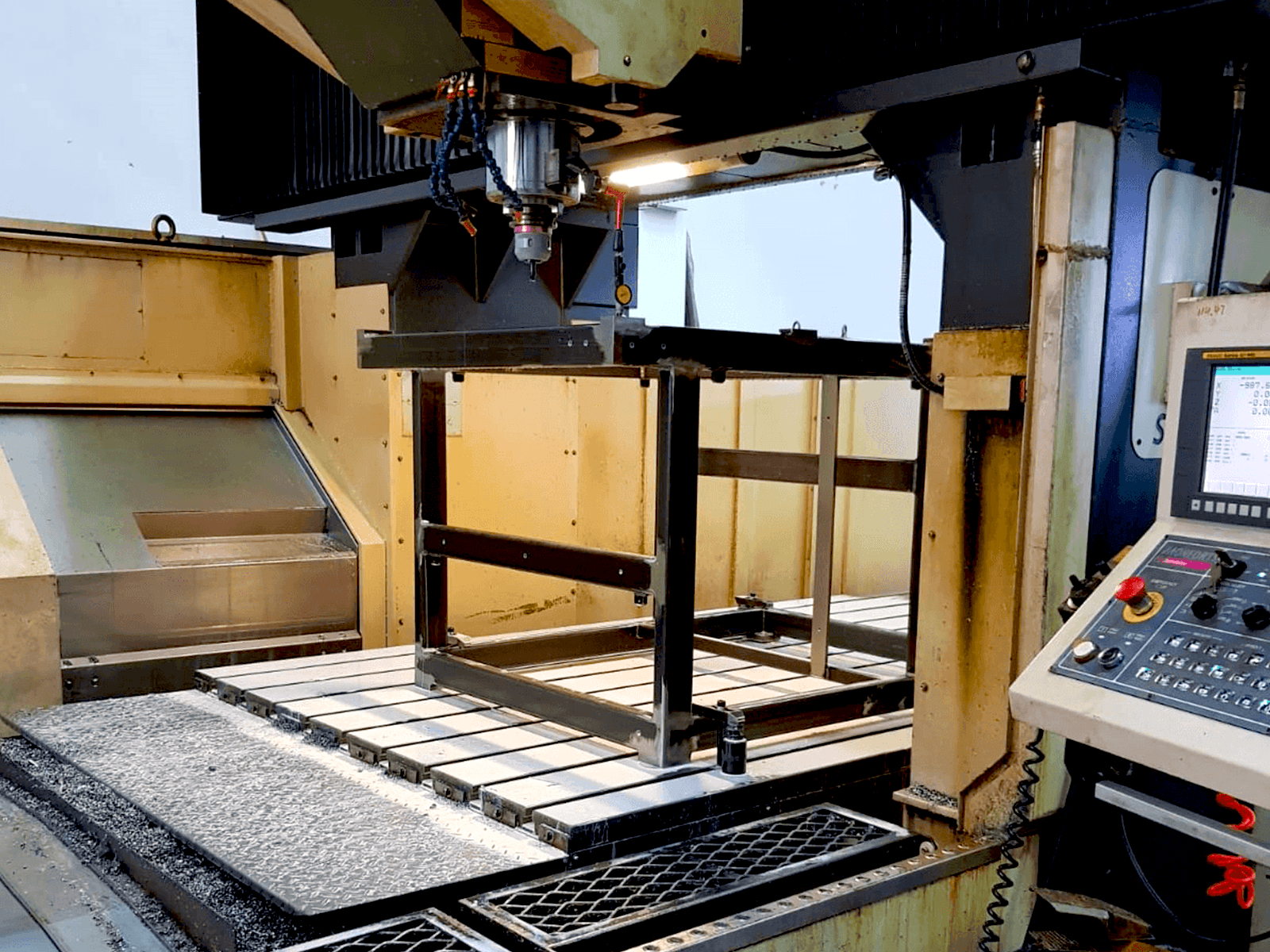

Milling and Turning Department

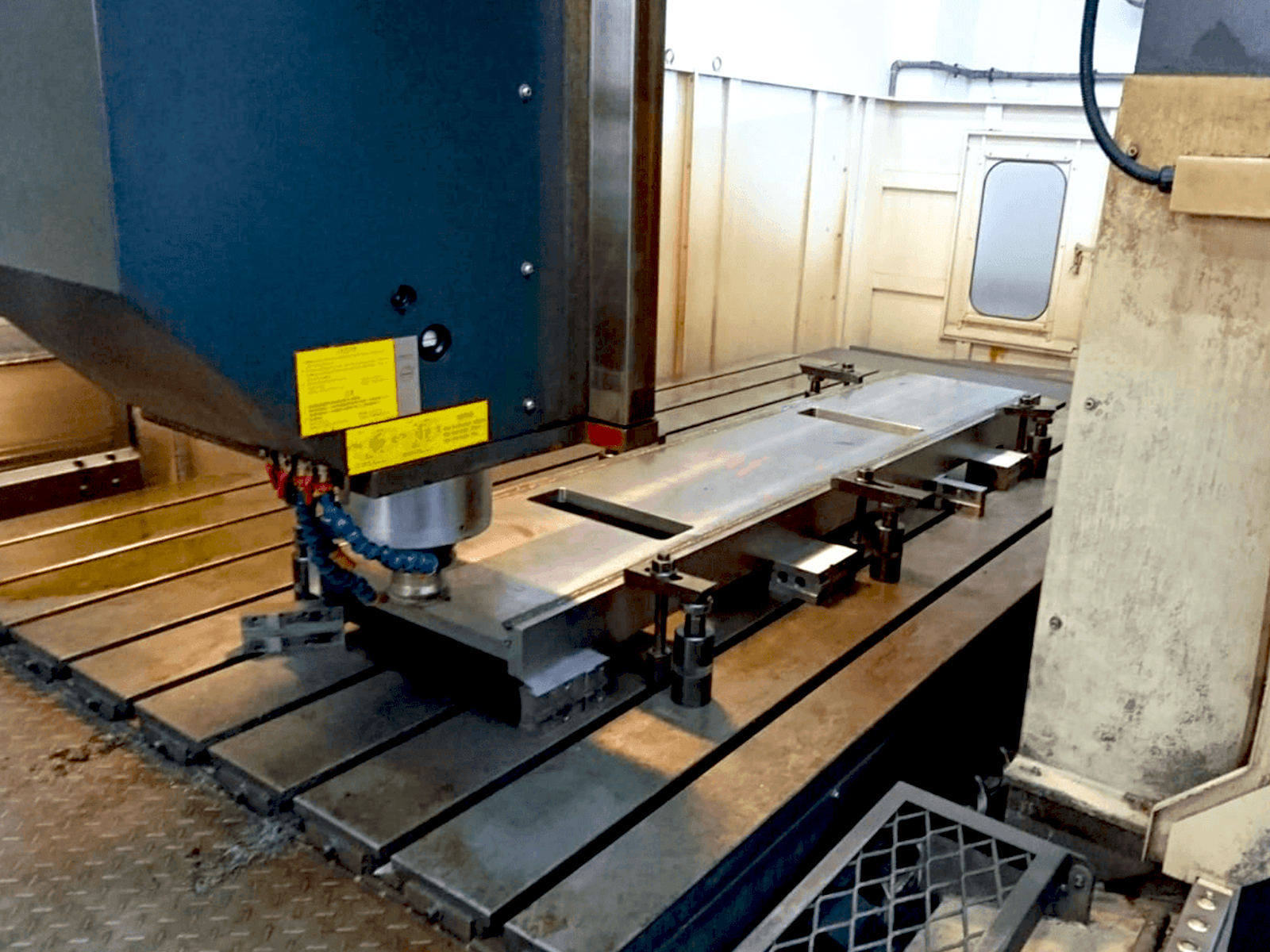

Equipped with CNC milling machines, lathes and large CNC Double-Column Machining Centers, we are capable of fabricating parts varying from small yet complex parts to large parts with intricate features.

- Components can be milled in lengths up to 3,200mm widths up to 2,000mm.

- Turning service can be provided for parts up to ø400 in diameter and 1,000mm long, bar feed up to 12" long and 3" in diameter all to tight tolerances.

- We work with a wide variety of materials including, but not limited to:

steel, stainless steel, aluminium, nylon, delrin; ABS, acrylic, teflon, peek, polyurethane and silicon.

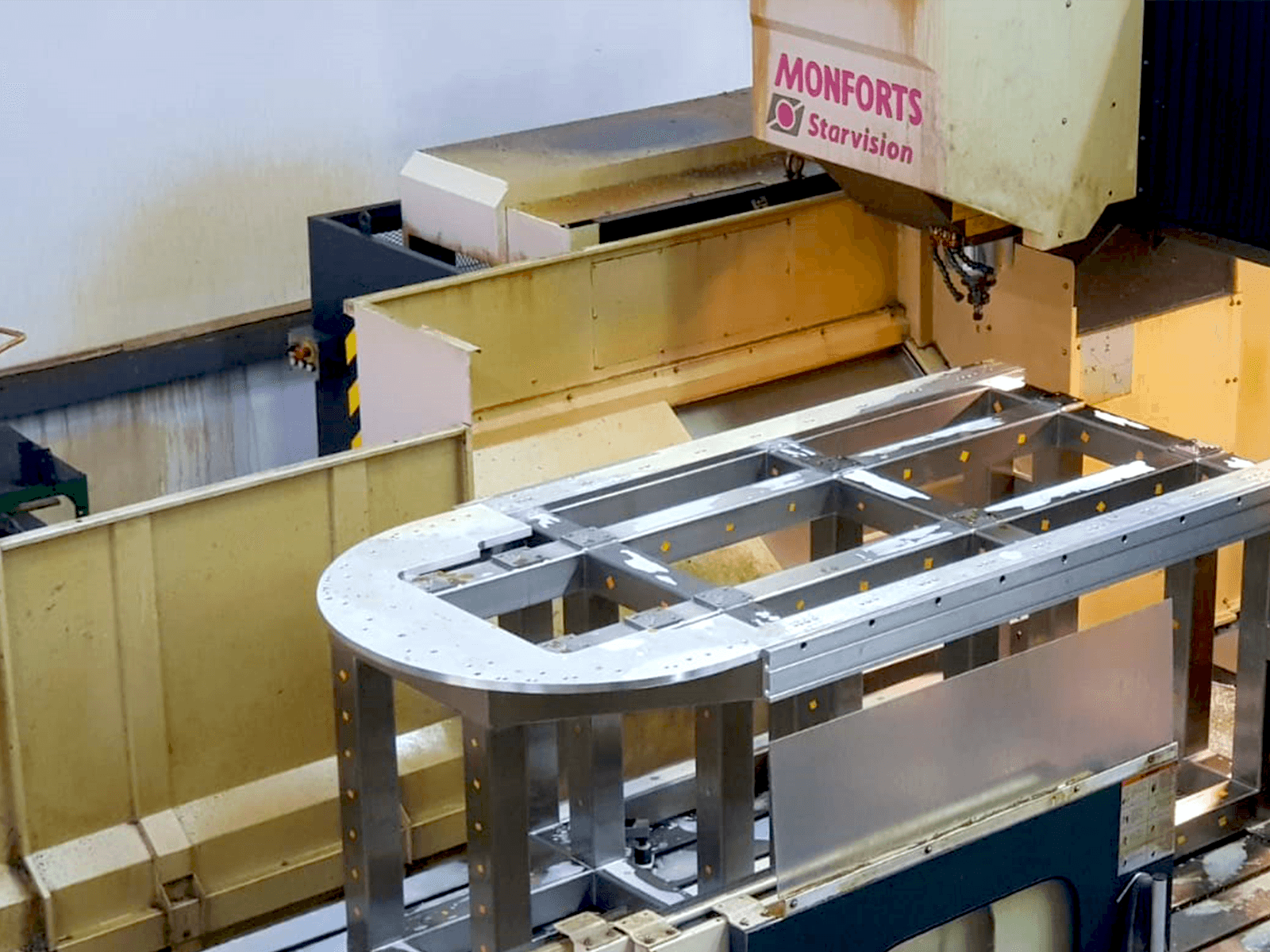

CNC Double Column Machining Centers

| Brand Model | Max RPM | X | Y | Z |

|---|---|---|---|---|

| Monfort FS3220 | 6,000 | 3,200mm | 2,000mm | 1,100mm |

| Kitamura 8F | 12,000 | 2,200mm | 1,085mm | 1,000mm |

| Mazak AJV-35/60 | 3,200 | 1,500mm | 800mm | 510mm |

CNC Milling Centers

| Brand Model | Max RPM | X | Y | Z |

|---|---|---|---|---|

| Mazak V414 | 7,000 | 810mm | 410mm | 460mm |

| Mazak FJV-200 | 12,000 | 560mm | 410mm | 410mm |

| Mazak FJV-250 | 12,000 | 1,020mm | 510mm | 460mm |

| Mazak VTC-200B | 10,000 | 1,120mm | 510mm | 510mm |

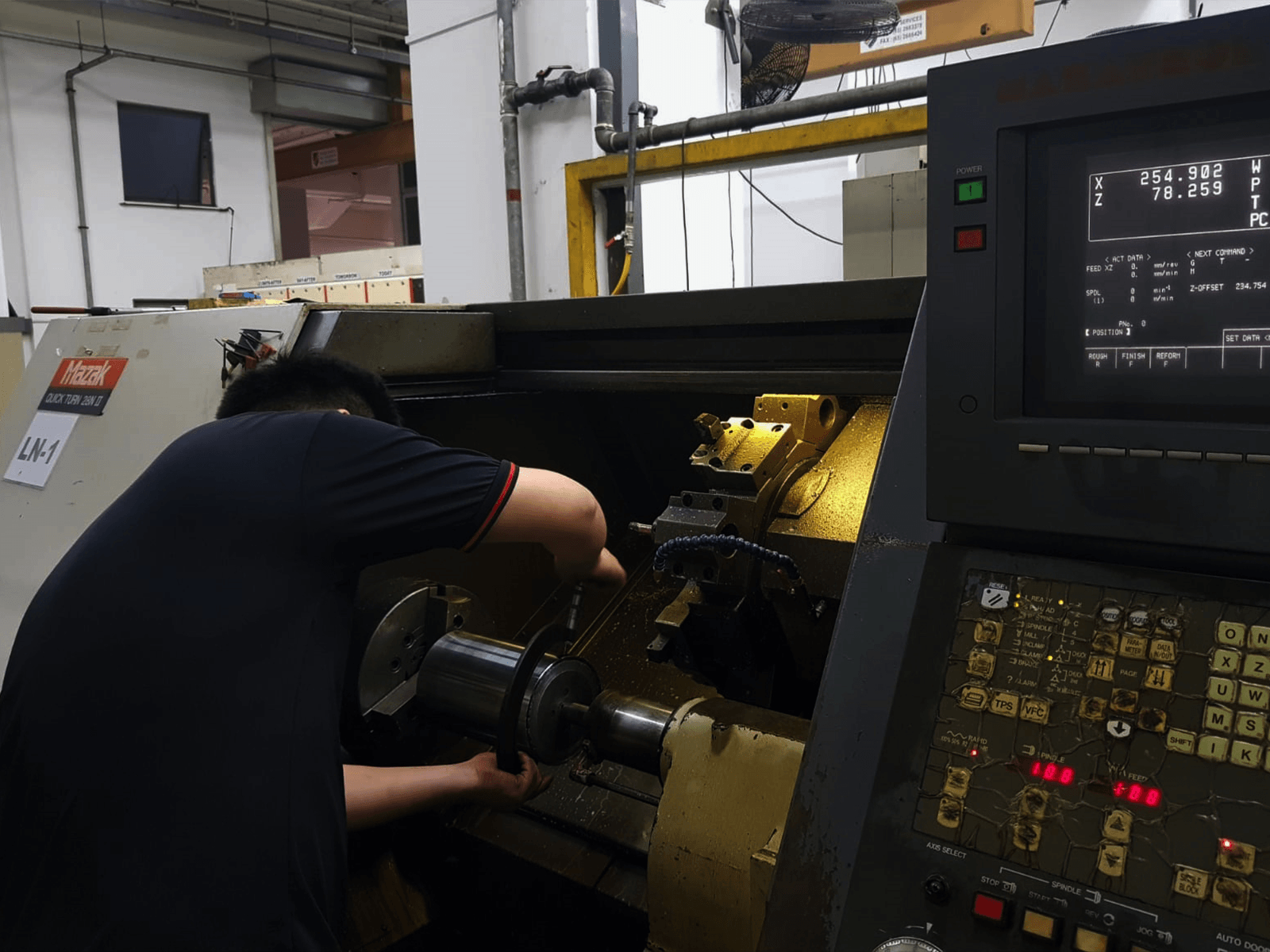

CNC Lathes

| Brand Model | Max RPM | Diameter | Length |

|---|---|---|---|

| Mazak QT-28 | 3,000 | 400mm | 1,010mm |

| Mazak QT-18N | 3,600 | 255mm | 500mm |

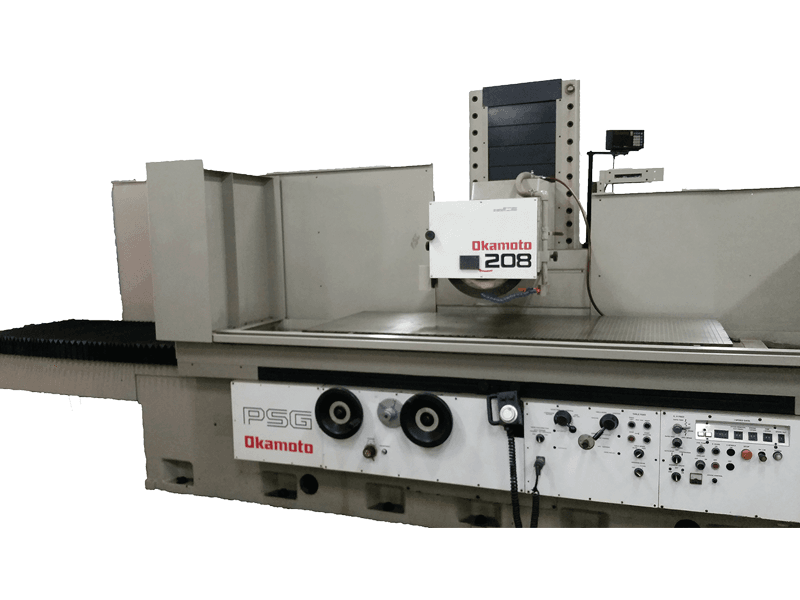

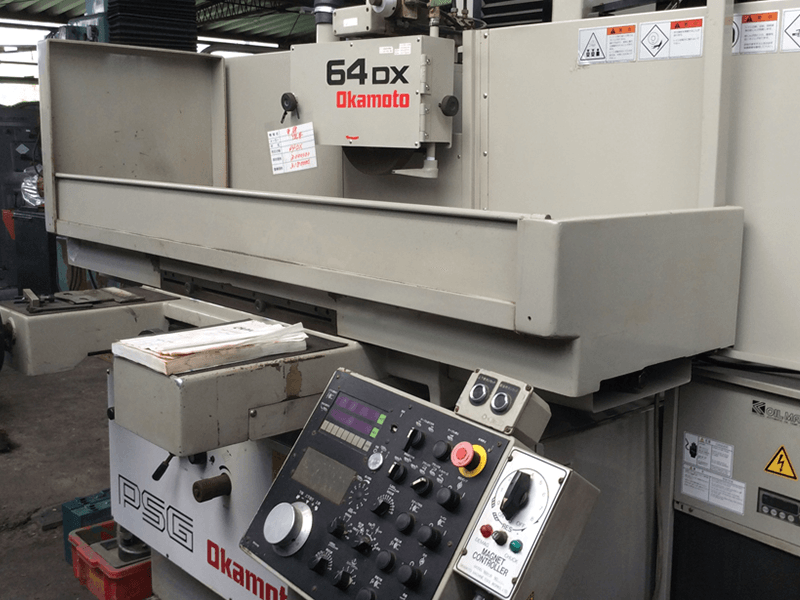

Grinding Department

At Akai, we grind a variety of metals, including steel, aluminium, stainless steel, nickel alloys and hardened steel (>55 HRC). We are able to grind parts up to 2,000mm in length and 1,000mm wide.

- Our extensive experience with regrinding, refurbishing and refinishing of upper and lower die plates used in press machines and other machine parts allow us to turn around orders with typical lead times of one week.

- Emergency repair or rush request services are also available.

Grinding Tolerances - Parallelism, Flatness

- Our largest surface grinder can achieve 0.02 parallelism. However, flatness is much more difficult to achieve when working with large parts; and our flatness capabilities approaches 0.01mm/500mm*.

*varies with material thickness.

| Brand Model | X | Y |

|---|---|---|

| Okamoto-208 FX | 2000mm | 1000mm |

| Okamoto-84 DX | 800mm | 400mm |

| Okamoto-64 DX | 600mm | 400mm |

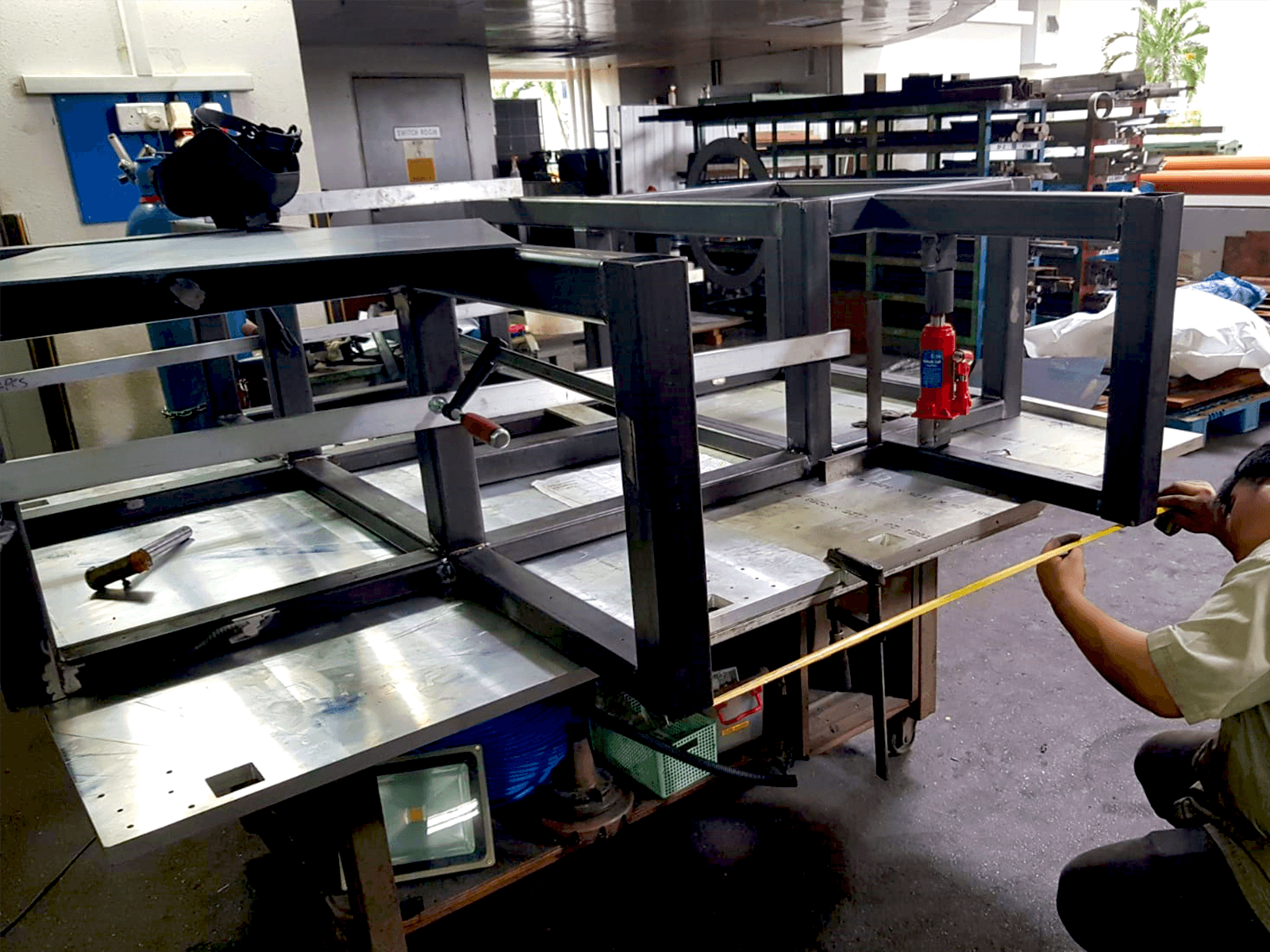

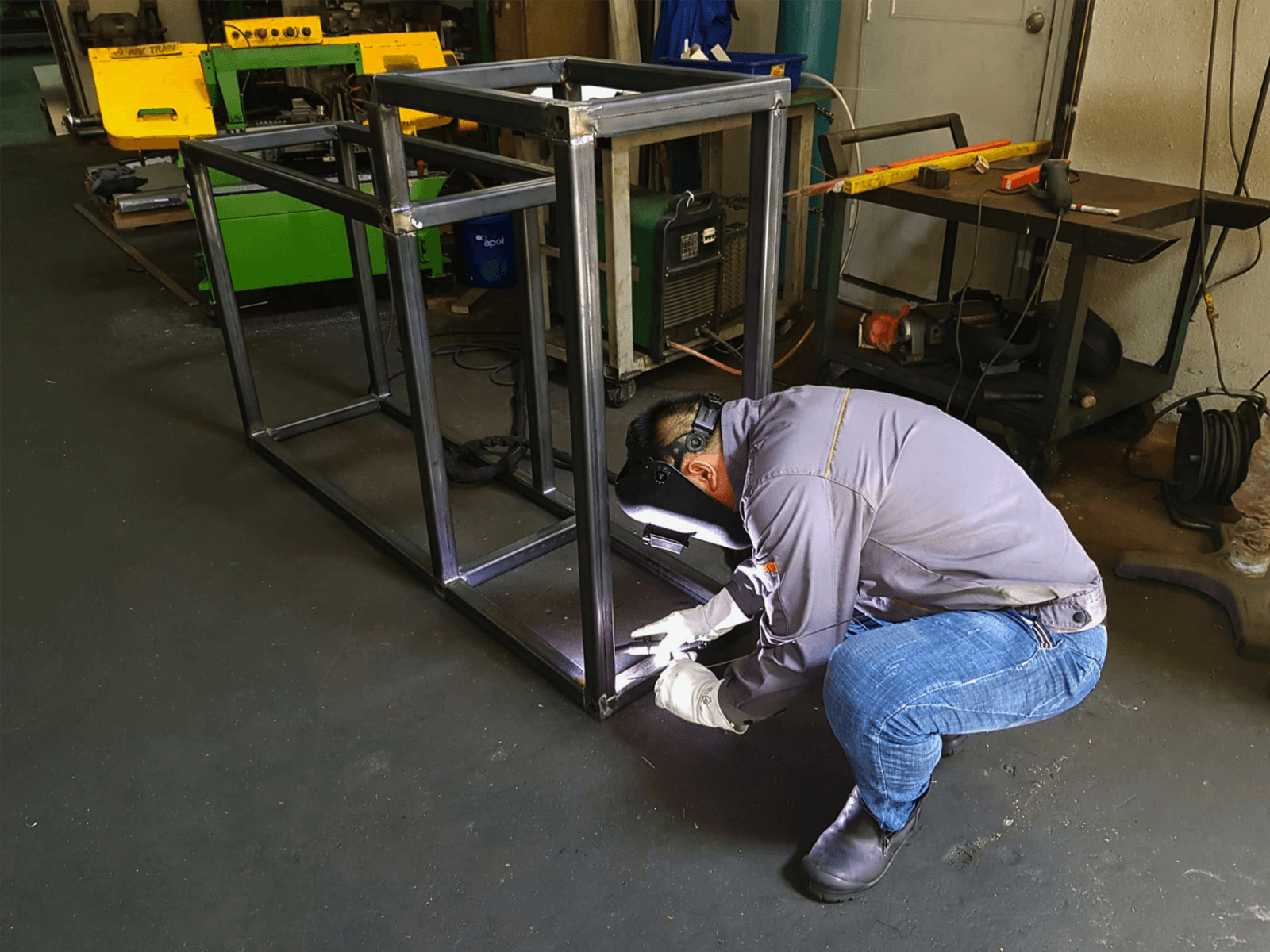

Welding Department

At Akai, we fabricate a wide variety of units by welding an assembly of structural tubing, channels or beams together. We are experts at joining two or more steels, alloys or metal pieces into one weldment assembly.

- Heavy and large weldments that we fabricate includes, but are not limited to, heavy frames and machine structures.

- Weldment assembly that have critical mounting locations of other parts such as cylinders, brackets or bearings are controlled in-house by performance of CNC process to ensure conformance of tight tolerances.

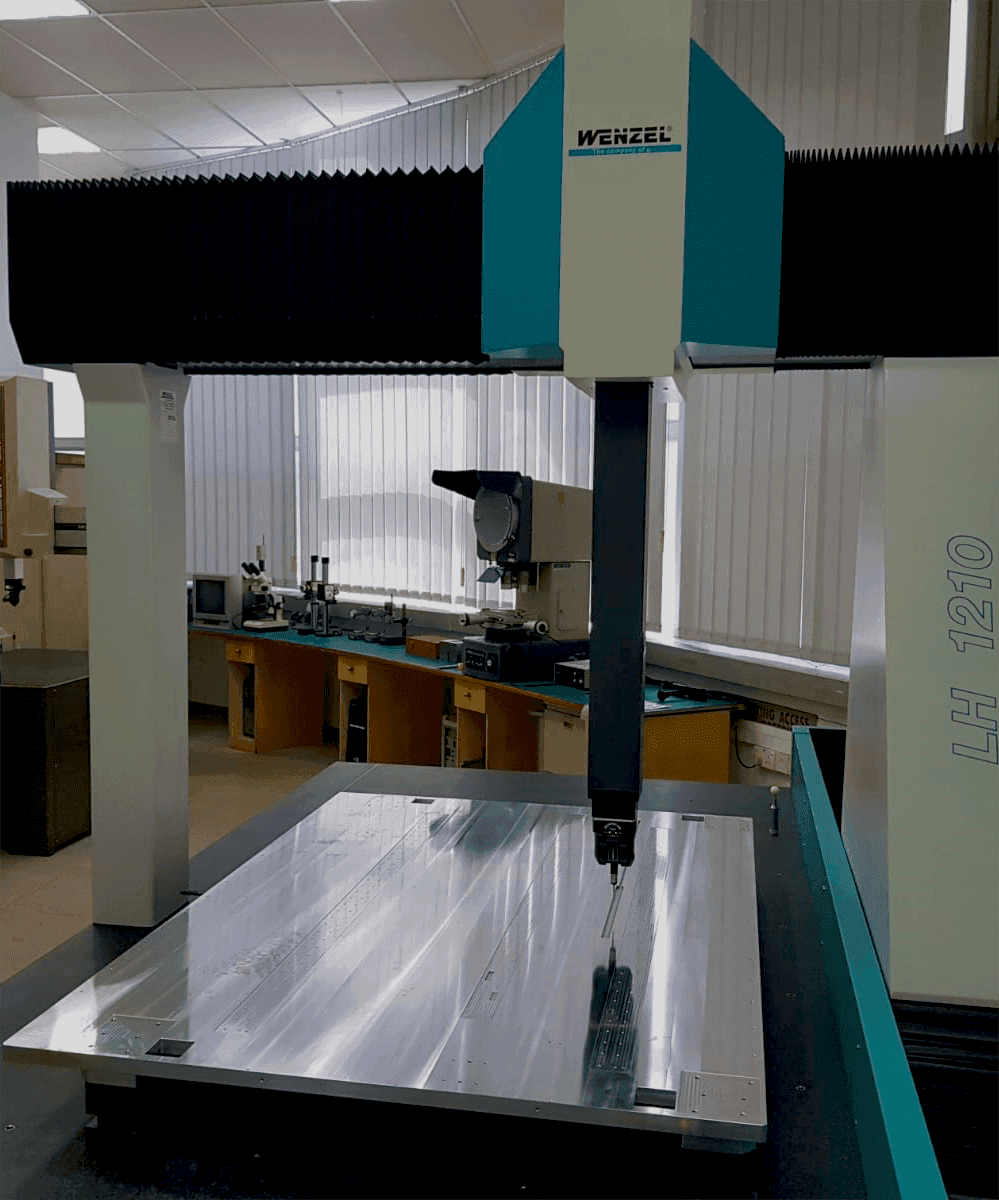

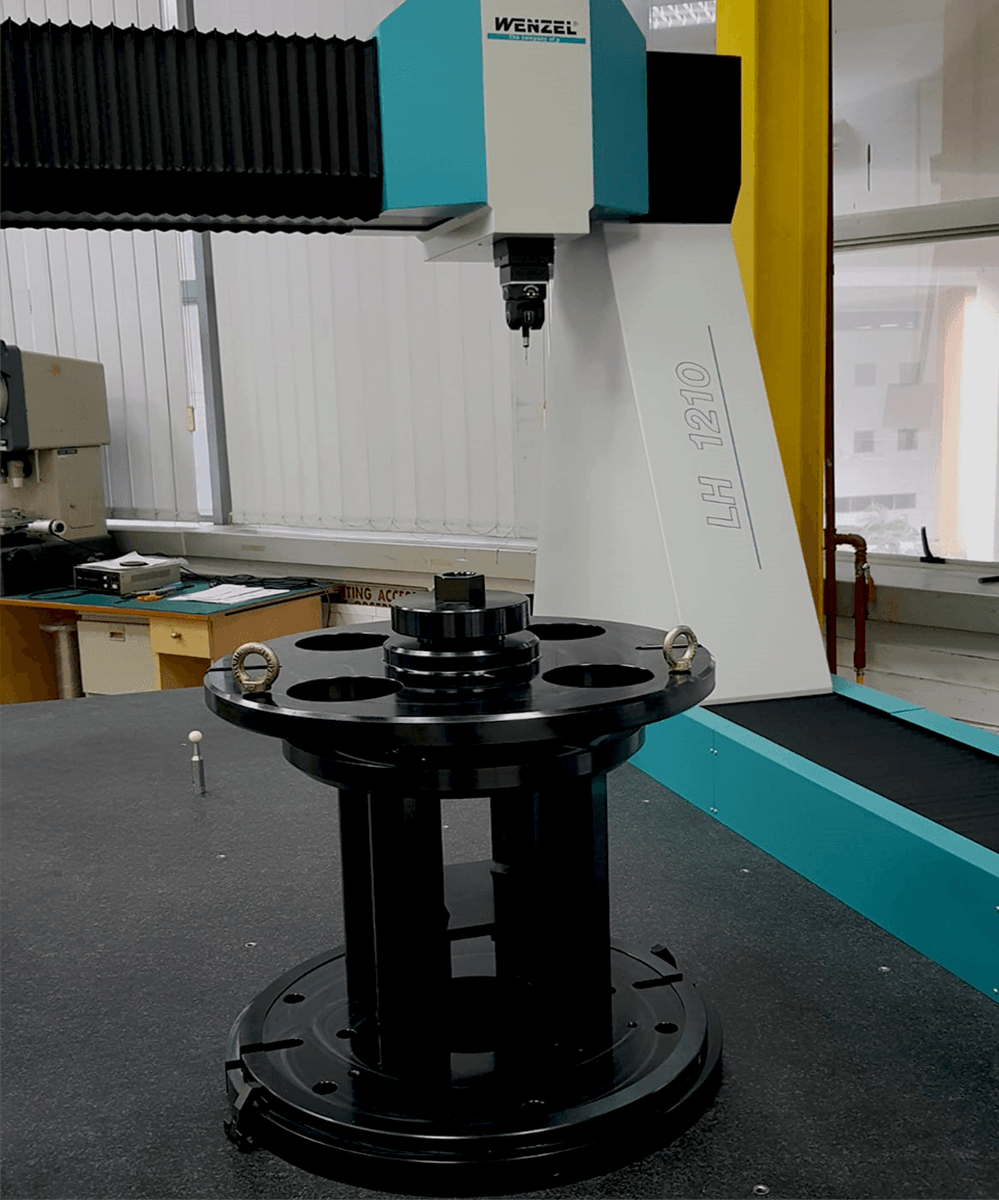

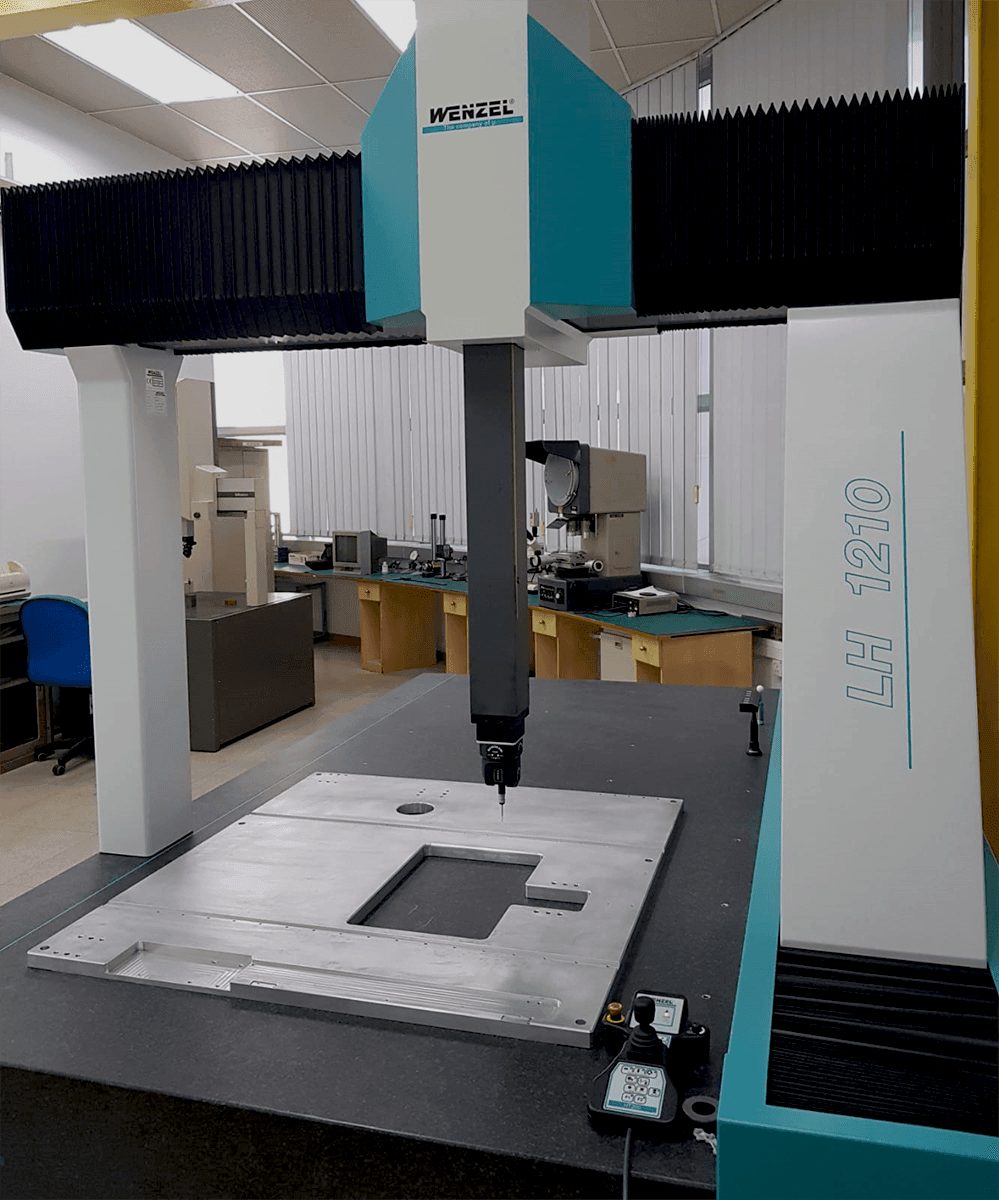

Quality Assurance

ISO 9001:2015 Certified

At Akai, we believe in ensuring our fabrications not only match our customers' needs, but are of the finest quality as well. To fulfil that promise, we pursued and have been accredited the ISO 9001:2015 certification after completing comprehensive external quality reviews.

The ISO 9001:2015 standard is based on a number of quality management principles, further demonstrating our customer-centric focus and a company-wide commitment to continuous service improvements.

Interested in our offerings?

Contact us today and be a part of the Akai family.